Càball Ionnsramaid En 50288-7 Sgrion Coitcheann PVC Armachd Cleachdadh ann an Àrainneachdan Garbh Sgrionaichean Foil Alùmanaim Coitcheann

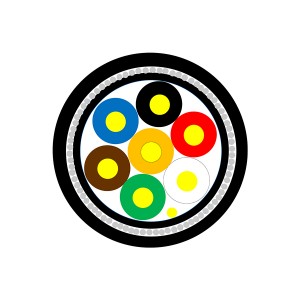

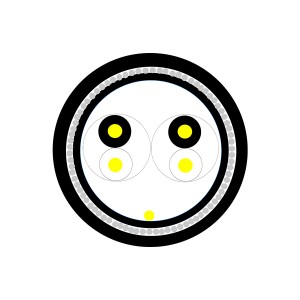

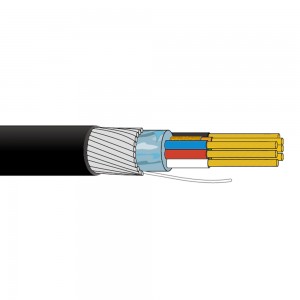

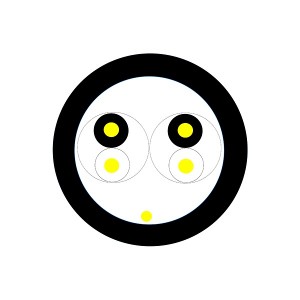

Togail

Stiùiriche: Copar Annealed Sreathach

Insaladh cridhe: XLPE, thairis air stiùiriche air a phasgadh le teip MICA

Sgrion: OS Aluminum/PET + TC Uèir drèanaidh • Slige a-staigh: LSZH, dubh

Armachd: Uèir stàilinn ghalbhanaichte

Slige a-muigh: LSZH, dubh

Stiùireadh Stàlaidh

Teòthachd Stàlaidh: Os cionn 0ºC

Teòthachd Obrachaidh: -15ºC ~ 65ºC

Bholtaids Reicte: 90V, 300V, 500V

Bholtaids Deuchainn (DC): 2000V Eadar Stiùirichean

2000V Eadar Gach Stiùiriche agus Armachd

Coileanadh Dealain

Tiughas Inslithe as ìsle

| Meud an Stiùiriche (mm2) | Tiughas beag (mm) | |||||

| Bholtaids Reataichte | ||||||

| 90V | Neart Dielectric | 300V | Neart Dielectric | 500V | Neart Dielectric | |

| 0.5 | 0.2 | ≥0.75KVac no ≥1.5KVdc | 0.26 | ≥1.0KVac no ≥2.0KVdc | 0.44 | ≥2.0KVac no ≥3.0KVdc |

| 0.75 | 0.2 | 0.26 | 0.44 | |||

| 1.0 | 0.26 | 0.26 | 0.44 | |||

| 1.5 | 0.3 | 0.35 | 0.44 | |||

Feartan Coitcheann

| Meud an t-seoltaiche (mm2) | Clas Stiùiriche | DCR as àirde (Ω/km) | Luachan Comas Co-phàirteach as àirde pF/m | Comas as àirde Neo-chothromachadh Paidhrichean/Ceathraichean Polyolefin (pF/500m) | Co-mheas as àirde clì/deas (μH/Ω) | |

| Poile-olefin (nf/km) | PVC (nf/km) | |||||

| 0.5 | 5 | 39.7 | 150 | 250 | 500 | 25 |

| 0.75 | 5 | 26.5 | 150 | 250 | 500 | 25 |

| 1.0 | 5 | 19.8 | 150 | 250 | 500 | 25 |

| 1.5 | 2 | 13.5 | 150 | 250 | 500 | 40 |

90V, ioma-phaidhir, PE inslithe, sgrìonadh iomlan

| Àireamh nam Pàirean | Stiùiriche | Tiughas Inslithe (mm) | Air a sgrìonadh | Tiughas na Slige (mm) | Trast-thomhas iomlan (mm) | |

| Meud (mm2) | Clas | |||||

| 1 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.6 | 4.5 |

| 2 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.7 | 6.9 |

| 3 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.7 | 7.5 |

| 4 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.8 | 8.3 |

| 5 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 6 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.9 | 10.1 |

| 8 | 0.5 | 2, 5 | 0.35 | Al-foil | 1 | 11.5 |

| 10 | 0.5 | 2, 5 | 0.35 | Al-foil | 1.1 | 13.2 |

| 1 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.7 | 5.3 |

| 2 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.8 | 7.8 |

| 3 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.8 | 8.3 |

| 4 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.9 | 9.3 |

| 5 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.9 | 10 |

| 6 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1 | 11.1 |

| 8 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1 | 12.3 |

| 10 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1.1 | 14 |

| 1 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.6 | 4.9 |

| 2 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.7 | 7.6 |

| 3 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.7 | 8.2 |

| 4 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 5 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.9 | 10.2 |

| 6 | 0.75 | 2, 5 | 0.35 | Al-foil | 1 | 11.3 |

| 8 | 0.75 | 2, 5 | 0.35 | Al-foil | 1.1 | 12.4 |

| 10 | 0.75 | 2, 5 | 0.35 | Al-foil | 1.2 | 14.8 |

| 1 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.7 | 5.7 |

| 2 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.8 | 8.4 |

| 3 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.9 | 9.4 |

| 4 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 0.9 | 10.1 |

| 5 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1 | 11.2 |

| 6 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1 | 12.1 |

| 8 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1.1 | 13.7 |

| 10 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braidichte | 1.2 | 15.5 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 6.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 9.8 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 10.6 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1 | 11.5 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.1 | 12.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.2 | 14 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.3 | 15.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.3 | 17.8 |

| 1 | 1.5 | 2, 5 | 0.45 | Al-foil | 0.7 | 6.5 |

| 2 | 1.5 | 2, 5 | 0.45 | Al-foil | 0.9 | 10.4 |

| 3 | 1.5 | 2, 5 | 0.45 | Al-foil | 1 | 11.5 |

| 4 | 1.5 | 2, 5 | 0.45 | Al-foil | 1 | 12.4 |

| 5 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.1 | 13.8 |

| 6 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.2 | 15.3 |

| 8 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.3 | 17.4 |

| 10 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.4 | 19.9 |

| 1 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 0.8 | 7.3 |

| 2 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1 | 11.4 |

| 3 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1 | 12.3 |

| 4 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1.1 | 13.4 |

| 5 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1.2 | 14.8 |

| 6 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1.3 | 16.3 |

| 8 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1.4 | 18.4 |

| 10 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braidichte | 1.4 | 20.7 |

300V, ioma-phaidhir, PE inslithe, air a sgrìonadh gu h-iomlan

| Àireamh nam Pàirean | Stiùiriche | Tiughas Inslithe (mm) | Air a sgrìonadh | Tiughas na Slige (mm) | Trast-thomhas iomlan (mm) | |

| Meud (mm2) | Clas | |||||

| 1 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.6 | 4.7 |

| 2 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.7 | 7.3 |

| 3 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.1 |

| 4 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.7 |

| 5 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.7 |

| 6 | 0.5 | 2, 5 | 0.4 | Al-foil | 1 | 10.8 |

| 8 | 0.5 | 2, 5 | 0.4 | Al-foil | 1 | 12.1 |

| 10 | 0.5 | 2, 5 | 0.4 | Al-foil | 1.1 | 13.9 |

| 1 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.7 | 5.5 |

| 2 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 8.1 |

| 3 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 8.7 |

| 4 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 9.7 |

| 5 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1 | 10.7 |

| 6 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1 | 11.6 |

| 8 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.1 | 13.1 |

| 10 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.2 | 14.9 |

| 1 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.3 |

| 2 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.7 | 8.3 |

| 3 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.8 | 9.2 |

| 4 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.9 | 10.1 |

| 5 | 0.75 | 2, 5 | 0.4 | Al-foil | 1 | 11.3 |

| 6 | 0.75 | 2, 5 | 0.4 | Al-foil | 1 | 12.3 |

| 8 | 0.75 | 2, 5 | 0.4 | Al-foil | 1.1 | 14 |

| 10 | 0.75 | 2, 5 | 0.4 | Al-foil | 1.2 | 16.1 |

| 1 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 7.5 |

| 2 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 9.3 |

| 3 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 10.2 |

| 4 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 11.1 |

| 5 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1 | 12.1 |

| 6 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.1 | 13.3 |

| 8 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.2 | 15 |

| 10 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.3 | 17.1 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.8 | 6.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 9.8 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 0.9 | 10.6 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1 | 11.5 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.1 | 12.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.2 | 14 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.3 | 15.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil + TC Braidichte | 1.3 | 17.8 |

| 1 | 1.5 | 2, 5 | 0.5 | Al-foil | 0.7 | 6.7 |

| 2 | 1.5 | 2, 5 | 0.5 | Al-foil | 1 | 11 |

| 3 | 1.5 | 2, 5 | 0.5 | Al-foil | 1 | 11.8 |

| 4 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.1 | 13 |

| 5 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.2 | 14.4 |

| 6 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.3 | 16 |

| 8 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.4 | 18.2 |

| 10 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.4 | 20.6 |

| 1 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 0.8 | 7.5 |

| 2 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1 | 11.8 |

| 3 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.1 | 12.8 |

| 4 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.2 | 14 |

| 5 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.2 | 15.2 |

| 6 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.3 | 16.8 |

| 8 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.4 | 19 |

| 10 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braidichte | 1.4 | 21.4 |

500V, ioma-phaidhir, PE inslithe, air a sgrìonadh gu h-iomlan

| Àireamh nam Pàirean | Stiùiriche | Tiughas Inslithe (mm) | Air a sgrìonadh | Tiughas na Slige (mm) | Trast-thomhas iomlan (mm) | |

| Meud (mm2) | Clas | |||||

| 1 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.6 | 5.5 |

| 2 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.8 | 8.9 |

| 3 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.9 | 9.8 |

| 4 | 0.5 | 2, 5 | 0.6 | Al-foil | 1 | 10.7 |

| 5 | 0.5 | 2, 5 | 0.6 | Al-foil | 1 | 11.7 |

| 6 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.1 | 13 |

| 8 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.2 | 14.8 |

| 10 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.3 | 17 |

| 1 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.8 | 6.5 |

| 2 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.9 | 9.8 |

| 3 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.9 | 10.6 |

| 4 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 11.5 |

| 5 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.1 | 12.7 |

| 6 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.2 | 14 |

| 8 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.3 | 15.8 |

| 10 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.3 | 17.8 |

| 1 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.7 | 6.1 |

| 2 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.9 | 9.7 |

| 3 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.9 | 10.5 |

| 4 | 0.75 | 2, 5 | 0.6 | Al-foil | 1 | 11.6 |

| 5 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.1 | 12.9 |

| 6 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.2 | 14.2 |

| 8 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.3 | 16.2 |

| 10 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.3 | 18.4 |

| 1 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.8 | 6.9 |

| 2 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 10.7 |

| 3 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 11.5 |

| 4 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 12.4 |

| 5 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.1 | 13.7 |

| 6 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.2 | 15 |

| 8 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.3 | 17 |

| 10 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.4 | 19.4 |

| 1 | 1 | 2, 5 | 0.6 | Al-foil | 0.7 | 6.5 |

| 2 | 1 | 2, 5 | 0.6 | Al-foil | 0.9 | 10.4 |

| 3 | 1 | 2, 5 | 0.6 | Al-foil | 1 | 11.5 |

| 4 | 1 | 2, 5 | 0.6 | Al-foil | 1 | 12.4 |

| 5 | 1 | 2, 5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 6 | 1 | 2, 5 | 0.6 | Al-foil | 1.2 | 15.3 |

| 8 | 1 | 2, 5 | 0.6 | Al-foil | 1.3 | 17.4 |

| 10 | 1 | 2, 5 | 0.6 | Al-foil | 1.4 | 19.9 |

| 1 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.8 | 7.3 |

| 2 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 11.4 |

| 3 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 12.3 |

| 4 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.1 | 13.4 |

| 5 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.2 | 14.8 |

| 6 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.3 | 16.3 |

| 8 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.4 | 18.4 |

| 10 | 1 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.4 | 20.7 |

| 1 | 1.5 | 2, 5 | 0.6 | Al-foil | 0.8 | 7.3 |

| 2 | 1.5 | 2, 5 | 0.6 | Al-foil | 1 | 11.6 |

| 3 | 1.5 | 2, 5 | 0.6 | Al-foil | 1 | 12.6 |

| 4 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 5 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.2 | 15.4 |

| 6 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.3 | 17 |

| 8 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.4 | 19.3 |

| 10 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.4 | 22 |

| 1 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 0.8 | 7.9 |

| 2 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1 | 12.6 |

| 3 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.1 | 13.6 |

| 4 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.2 | 14.8 |

| 5 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.2 | 16.4 |

| 6 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.3 | 17.8 |

| 8 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.4 | 20.1 |

| 10 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braidichte | 1.4 | 22.7 |

Sgrìobh do theachdaireachd an seo agus cuir thugainn i